Adhesive Peel Tester companies|peel testing materials : distribute Scratch testing carried out by our experts is invaluable to gain insight into materials . Resultado da 27 de dez. de 2023 · Servidor Avançado Free Fire: Download APK 66.35.0 Advance FF (link direto) Jogadores já podem baixar o APK do Servidor .

{plog:ftitle_list}

Bet7k Brasil – Jogue Mais de 7000 Jogos no Cassino Oficial. O Bet7k é um dos .

Peel testing allows accurate measurement of the performance of seals, coatings and adhesives and gives invaluable information to resolve failure investigations for adhesives failure and optimize processing parameters.Scratch testing carried out by our experts is invaluable to gain insight into materials .

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing .ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different .A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as .

Cut and peel testing. Cataplasma testing – This is similar to the ‘cut and peel’ test process, but still not exactly the same. This test will put the adhesive through a similar climate in which the end-product will likely be exposed. So, .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .

Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials.Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330

To ensure quality, manufacturers of products like tape, labels, and wallpaper rely on adhesion testing. Without proper bonding between materials, it is possible for products to peel away or fail prematurely, which could compromise the manufacturer’s reputation as well as market share.. John Bogart, managing director of Kett US, explained, “To create products that require .

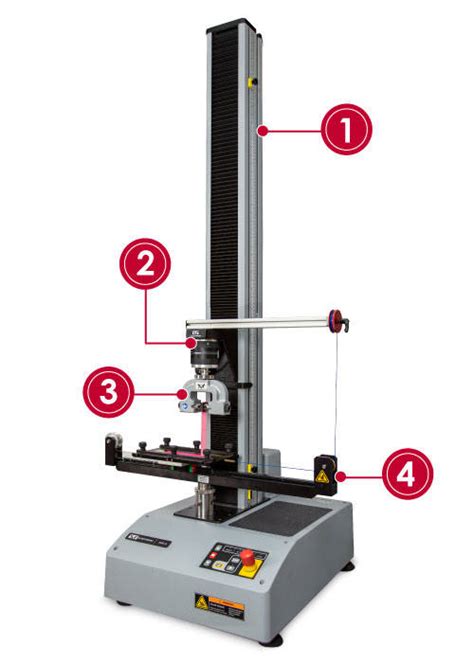

Peel testers, or peel test machines, are universal test machines specially configured to determine the adhesive peel strength or the strength of the adhesive bond between two materials. Each peel tester is configured to your test requirements by our application engineers with the correct controller, grips, and accessories.ASTM D3330-- Standard Test Method for Peel Adhesion of Pressure Sensitive Tape ; ASTM D3654-- Standard Test Methods for Shear Adhesion of Pressure Sensitive Tapes ; . For more information on how Labthink can help your company profit through testing, please Click the button. About Labthink. The headquarters of Labthink is in Jinan, China; its . ISO 11343 is a standardized Wedge Peel Impact test method used to measure the resistance of high-strength structural adhesives to cleavage fracture at various speeds and user-defined temperatures. The impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into the adhesive bond securing two metallic .To conduct a peel test, a specimen is prepared by bonding two materials together using an adhesive. The sample is then mounted in a peel testing machine, which pulls one material away from the other at a specific speed and angle, usually 90° or 180°.The force required to separate the materials is continuously measured during the test.

This test is optimized for tapes with flexible backings, or tapes that are adhered to a similar flexible substrate. Unlike the 180 degree peel test and 90 degree peel test, the T-peel or trouser method is the easiest test to set up and conduct. These types of tests are often done on transfer tapes or at converting companies that may use tape to .

There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main . A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel .ASTM peel adhesion testing is a tool for quality assurance use. At ATS, it is our policy to provide our clients with the highest quality testing services. Our ISO 17025 accredited lab performs ASTM peel adhesion testing to the most stringent applicable standards and specifications.

Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw drive, the computer set the test speed directly for adhesive force the physical property of strength resistance.

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to.

Get quotation from a top manufacturer and supplier of peel, seal, bond, and adhesion strength test equipment. +91 9313 140 140 . . To put it simply, an Adhesion Testing Instrument is an innovative packaging industry instrument that helps companies to measure the adhesion strength or the peel ability of self-adhesive pressure-sensitive materials.Peel Strength Testing Trying to figure out how to evaluate adhesion? If so, then you should look into a peel strength test. This adaptable test and inspect solution is an efficient method of characterizing an adhesive bond, and it falls under the broader category of adhesion testing. Read on to learn more about this helpful [.]The 180° peel adhesion test is crucial for assessing the performance of adhesives in various applications, particularly in packaging, medical devices, and consumer products. . By following ASTM D3330 guidelines and utilizing advanced testing equipment like the Cell Instruments 180° peel adhesion tester, companies can ensure that their .

Peel testing typically involves several variables which must be managed in order to ensure consistent and repeatable tests. Those variables include angle of the peel, rate of the pull, pressure with which the adherands are pushed together, and the surface characteristics of the adherands. ASTM D6252 is a common test method to measure the peel adhesion of . (a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is .Fracture tear / peel force adhesion testing of rubber-to-rigid surfaces; Roller peel adhesion testing; Strebler tear adhesion testing; 90° peel for adhesion to metal; . A Smithers member company may on occasion transfer your personal information to another Smithers member company, in some cases outside the European Economic Area. .

A peel test is a basic form of mechanical testing that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

peel testing software

Falling Dart Impact Tester solution

Film Pendulum Impact Tester solution

Resultado da domingo, 18 de fevereiro de 2024. Como ver Shrek Terceiro? Descubra todas as ofertas de filmes online para ver Shrek Terceiro. Assistir ao filme .

Adhesive Peel Tester companies|peel testing materials